PODCAST

Pennsylvania Turfgrass Council – Dissecting Infield Playability

PODCAST: PLAY IN NEW WINDOW | DOWNLOAD

Podcast (podcast_associations): Play in new window | Download (Duration: 10:33 — 14.5MB) | Embed

Subscribe Email | TuneIn | RSS

Pennsylvania Turfgrass – Evan C. Mascitti and Andrew McNitt, PhD

A baseball often touches two different surfaces during the same play. This sets baseball apart from other ball sports. Most ground balls take their first bounce on the turf and are fielded on the infield skin (Figure 1). The concentration of play in this small area means that infield playability consumes much of the grounds crew’s focus. Experienced managers know instinctively when the ball is reacting the way they want, and they can produce a consistent surface despite changing weather conditions. Playability can be an ambiguous term because it is easy to observe but hard to describe.

This article unpacks infield playability by combining practical observations with bite-size pieces of physics. We will cover the following ideas:

1. Consistency is king

2. Components of speed

3. Corkboard = plasticity + stiffness

Figure 1: Most action occurs on the infield skin.

Consistency is king

Above all else, infielders want a consistent, predictable surface. This means no surprises about how the ball will react from one hop to the next, and that the field will play identically throughout a game and over the season. Elite athletes can field almost any ball, fast or slow – so long as the bounces are the same, each and every time. Infielders prefer ground balls to “hug” the surface: a shallow path makes the ball easier to track and collect. The grass and dirt areas should have similar speed and the transition between them should be seamless.

Predictability is crucial for players to be able to do their jobs. If the final hop is deflected by just a few degrees, the ball can easily carom off the heel of a player’s glove or scoot beyond his reach.

Components of speed

Players and coaches sometimes ask us to “speed up” or “slow down” the infield, usually by adjusting the cutting height of the turf. Ball response is more nuanced than fast vs. slow, and canopy height plays only a minor role. However, it has been said that perception is reality, so a perceived change may satisfy such a request – even if we fib about having lowered the reels by 1/8″ or so. Ball response is divisible into three important elements: pace, bounce, and spin.

Pace

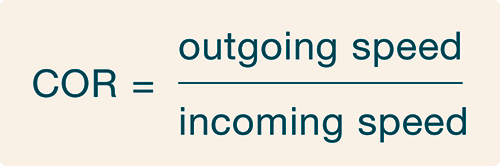

Pace is the relative velocity of a ball after impact. Infield pace is mostly determined by hardness and friction. It is measured as a simple ratio, the Coefficient of Restitution (COR):

There is limited research on infield pace, but data suggest that soil properties affect COR more than cutting height or thatch. Dr. Jim Brosnan measured COR on real infields and on research plots (Brosnan and McNitt, 2008a; b; 2011). Infield COR ranged from 0.4 to 0.6, meaning a ball retained 40 to 60 % of its initial velocity after the first bounce. COR was generally higher on skinned surfaces than synthetic turf, which had a similar (but slightly higher) COR than natural grass.

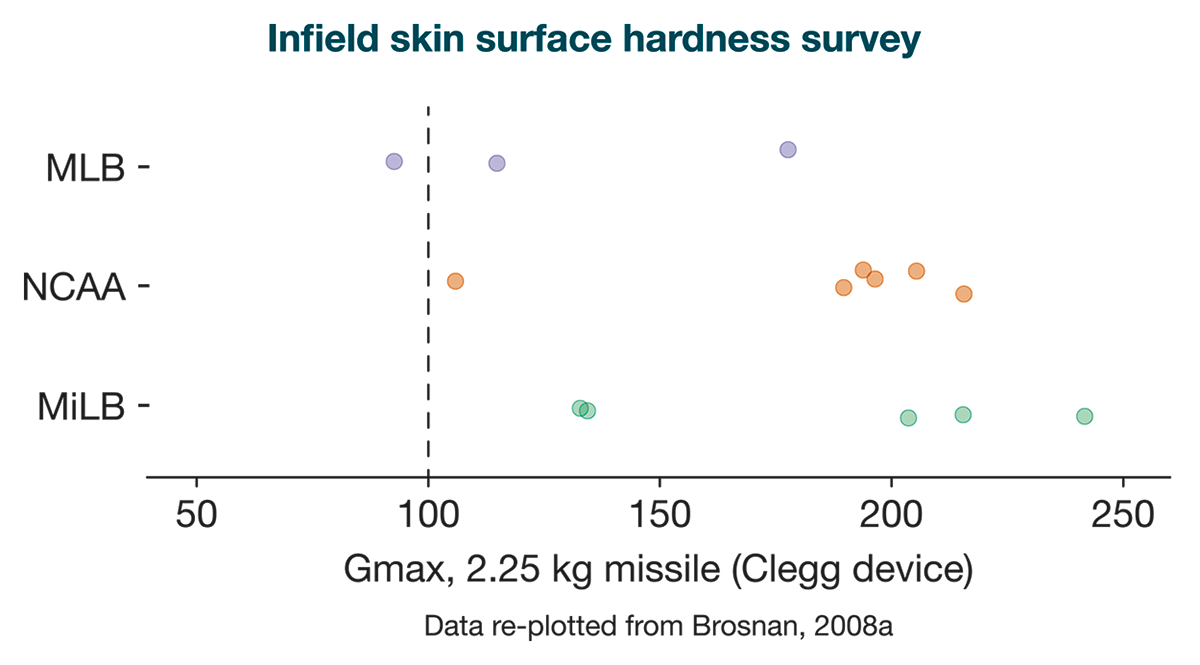

In the work by Dr. Brosnan, pace was closely related to surface hardness. Hardness is easy to measure with the familiar Clegg hammer or the F-355 device (for synthetic infields). Brosnan and McNitt (2008a) found that most infield skins had Clegg values well over 100 Gmax – much higher than values recommended for turf areas (Figure 2). However, it is worth noting that some fields in this study were substantially drier than typical game moisture. In a baseball context, hardness may be more useful for managing playability than safety, as baseball players are never tackled and rarely become injured by falling on the surface.

Figure 2: Surface hardness on baseball infields generally exceeds values recommended for American football.

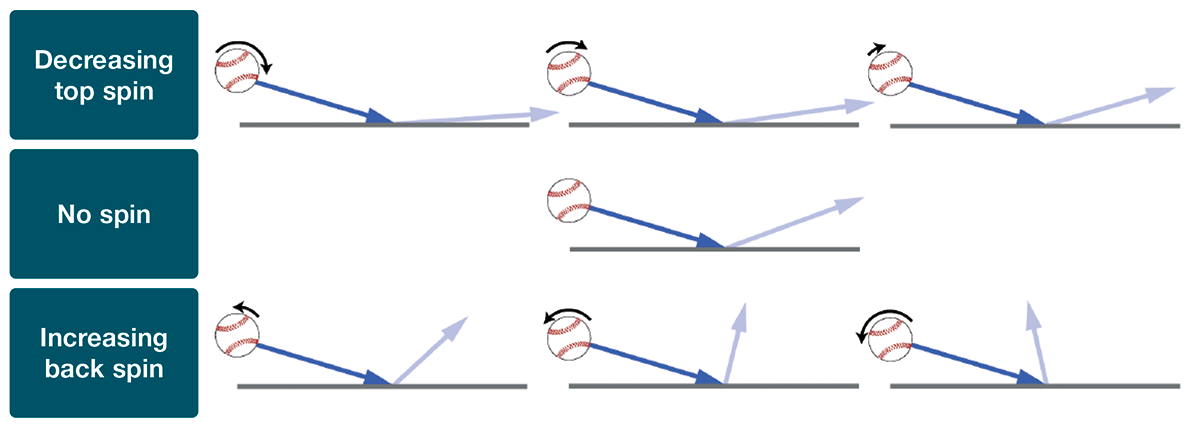

Ball-to-surface friction is determined by soil texture, presence of conditioner, and the all-important water content (Goodall et al., 2005). A thick conditioner layer reduces surface friction because the granules rotate like ball bearings as the ball shears against them. The ball will skid rather than checking up. Friction also affects the ball’s release angle, which in turn alters the bounce height (Figure 3).

Figure 3: If the ball can skid through impact, initial spin will influence the release angle. Adapted from Daish, 1972.

Bounce

The term bounce defines the vertical rebound of a ball after impact. Some research on cricket pitches suggests that the ball “speed” experienced by a real athlete is more related to bounce than pace. Adams et al. (2005) found that umpires’ perception of speed was more closely linked to the ball’s rebound height than its velocity. A higher bounce means the ball carries farther between bounces, leading to the perception of a faster surface.

Any debate about whether a perceived faster surface really has a greater pace or a greater bounce is purely scholastic, because the players’ experience is what ultimately matters. Bounce is related to hardness, and a harder surface will appear faster, even if only due to its higher bounce.

Spin

The influence of ball spin can be large or small, depending on the ball-to-surface friction coefficient μ (Daish, 1972). If μ is large, the ball “rolls” during impact and its new spin rate is determined by the original incoming velocity. If μ is small, the ball retains some spin as it skids through impact and its release angle is steeper (Figure 3, bottom panel). The latter is the usual case on closely-mown turfgrass.

You can observe this phenomenon during batting practice. It’s hard to hit accurate fungoes with full effort, so experienced coaches prefer a flatter but more controlled trajectory with some backspin. The steeper release angle helps compensate for lost velocity by increasing the ball’s carry after its first bounce.

It’s unusual for a ground ball to be hit with backspin during a game. Most ground balls have forward spin and release at an angle beneath their incoming trajectory (Figure 3, top panel).

Corkboard = plasticity + stiffness

We associate the word plastic with man-made products like disposable water bottles – but the word is actually derived from plastikos, an ancient Greek term for clay. Plastikos roughly translates to “fit for shaping.” Plasticity is perhaps the most useful property of clay: it helps potters to mold clay into useful objects before firing, and it allows a groundskeeper to scarify, shave, and pack soil with proper moisture. New grounds interns are quickly taught the sacred importance of moisture management.

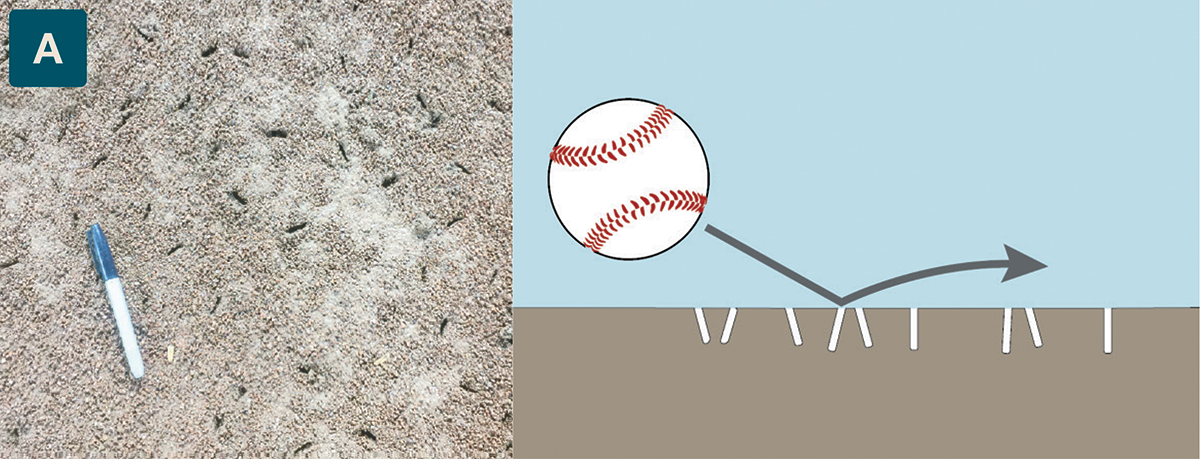

Plasticity is important for two reasons. First, it means the soil will be smoothly remolded around players’ cleats, rather than “chunking out” or shattering into chips. This delivers the coveted corkboard surface and minimizes the number of imperfections which could cause bad bounces, as shown in Figure 4. The second reason is that if a ball does hit one of the cleat marks, the soil will readily deform again – allowing the ball to continue its initial path. Plasticity provides the “give” which makes well-watered soil so nice to play on.

Figure 4: (A) This “corkboard” infield will not affect ball path because of its plastic yet stiff consistency. (B) Large, ragged cleat marks may cause erratic bounces, leading to errors or injuries.

Plasticity alone is not enough. Most fine-grained soils are plastic at high water contents, but many lose their shear strength when so much moisture is added. Such a soil can never provide stable footing if watered to a plastic condition – the players will sink and slide, leading to injuries. Other materials retain more stiffness when wetted above the plastic limit. Stiffness is a measure of the force needed to deform the soil. An ideal infield soil retains a plastic and stiff consistency, even under hot sun or during a rain game. Designing these types of mixes is a current research topic at Penn State. We recently created a laboratory method to measure the cleat-in/cleat-out effect. We are using the method to test infield mixes containing various clay minerals, since these respond differently as the soil wets or dries. Thanks are extended to the PA Turfgrass Council, KAFMO, and the SAFE Foundation for supporting the project.

On a synthetic turf infield “skin,” surface deformation happens differently. The fibers (rather than soil water) reduce the rotating and sliding of infill particles. The sand:rubber ratio and particle size distribution of the infill may also affect performance.

Summary

Ball response can be managed intuitively, but it helps to consider the underlying physics. Consistency is most important. What infielders experience as speed is a combined effect of pace, bounce, and spin. Conditioners reduce the effects of ball spin by lowering surface friction. The soil must be both stiff and plastic to achieve the coveted corkboard. Future research could define new playability measures and how to achieve them.

References

Adams, W.A., S.W. Baker, D.M. James, and R.J. Young. 2005. Measuring and Modelling the Bounce and Pace of County Championship Cricket Pitches. International Turfgrass Society Research Journal 10(1021-1026): 1021–1026.

Brosnan, J.T., and A.S. McNitt. 2008a. Surface Conditions of Highly Maintained Baseball Fields in the Northeastern United States : Part 1 , Non-Turfed Basepaths. Applied Turfgrass Science (April). doi: 10.1094/ATS-2008-0520-01-RS.

Brosnan, J.T., and A.S. McNitt. 2008b. Surface Conditions of Highly Maintained Baseball Fields in the Northeastern United States: Part 2, Synthetic versus Natural Turfgrass. Applied Turfgrass Science (April): 8. doi: 10.1094/ATS-2008-0520-02-RS.

Brosnan, J.T., A.S. McNitt, and T.J. Serensits. 2011. Effects of surface conditions on baseball playing surface pace. Journal of Testing and Evaluation 39(3). doi: 10.1520/JTE103215.

Daish, C.B. 1972. The Physics of Ball Games. The English Universities Press, London.

Goodall, S.A., K. Guillard, W.M. Dest, and K.R. Demars. 2005. Ball response and traction of skinned infields amended with calcined clay at varying soil moisture contents. International Turfgrass Society Research Journal 10: 1085–1093.